The automotive giant Nissan has recently found itself at the center of heated discussions regarding its substantial investment in Australian manufacturing operations. Company executives are standing firm on their decision, characterizing the significant expenditure as a strategic long-term investment rather than an unnecessary financial burden.

This bold stance comes amid growing scrutiny from industry analysts and shareholders who question the wisdom of such large-scale commitments. The debate has intensified as global automotive markets face unprecedented challenges and economic uncertainties.

Understanding the Investment Scale

Financial Commitment Breakdown

Nissan’s Australian manufacturing initiative represents one of the company’s most ambitious ventures outside its traditional markets. The investment encompasses multiple manufacturing facilities, advanced production technologies, and comprehensive workforce development programs.

Industry insiders estimate the total commitment could exceed several billion dollars over the next decade. This figure includes infrastructure development, technology acquisition, and ongoing operational costs that extend far beyond initial setup expenses.

Infrastructure Development Focus

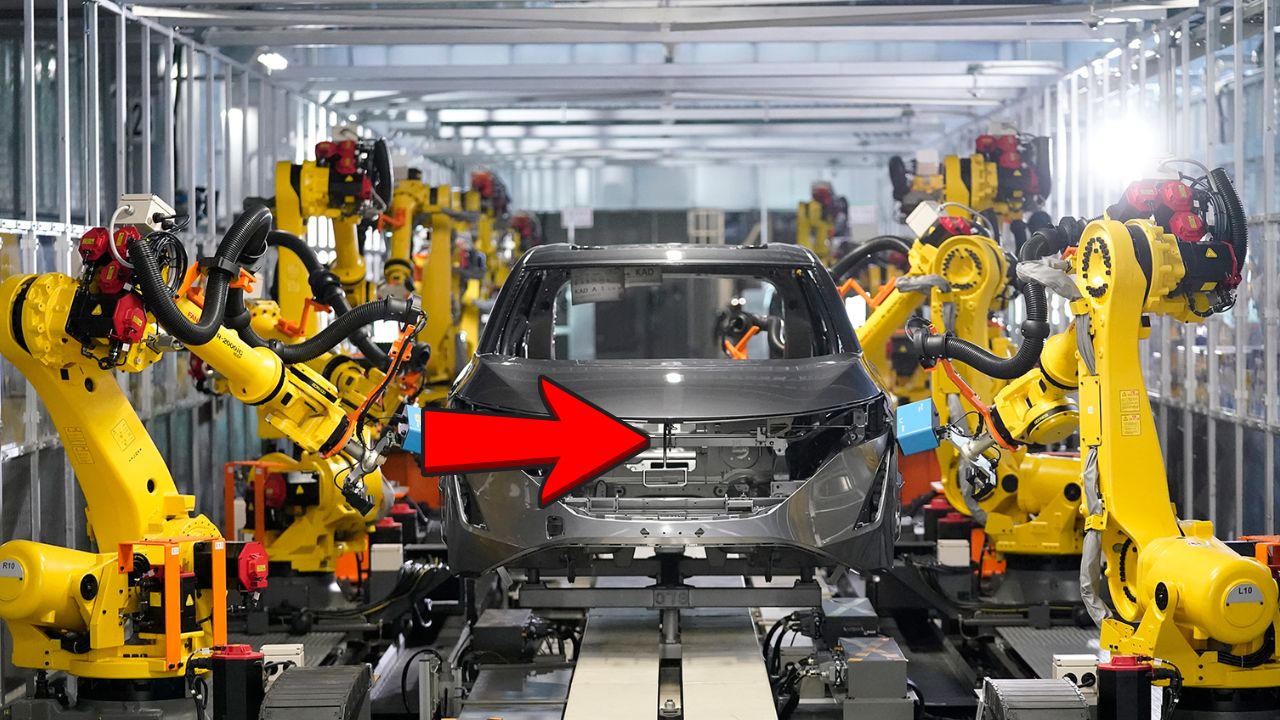

The company has prioritized building state-of-the-art manufacturing facilities equipped with cutting-edge automation systems. These installations are designed to meet both current production demands and future expansion requirements.

Advanced robotics and artificial intelligence integration form the backbone of these new facilities. The technology implementation aims to achieve unprecedented efficiency levels while maintaining strict quality control standards.

Strategic Rationale Behind the Decision

Market Positioning Advantages

Nissan executives argue that establishing a strong manufacturing presence in Australia provides significant competitive advantages in the Asia-Pacific region. The strategic location offers excellent access to emerging markets while maintaining proximity to established customer bases.

The company believes this positioning will prove invaluable as regional demand for vehicles continues growing. Market research data suggests substantial potential for expansion across Southeast Asian markets accessible from Australian production bases.

Supply Chain Optimization

Manufacturing locally allows Nissan to dramatically reduce supply chain complexities that have plagued the automotive industry recently. The company has experienced firsthand how global disruptions can severely impact production schedules and customer delivery commitments.

By establishing robust local production capabilities, Nissan aims to achieve greater supply chain resilience. This approach should minimize vulnerability to international shipping delays, port congestion, and geopolitical tensions affecting global trade routes.

Economic Impact and Community Benefits

Job Creation Initiatives

The manufacturing expansion is expected to create thousands of direct employment opportunities across various skill levels and specializations. Nissan has committed to hiring locally wherever possible, providing comprehensive training programs for new employees.

Indirect job creation through supplier networks and service providers could multiply the employment impact significantly. Economic modeling suggests each direct manufacturing job typically supports several additional positions in the broader community.

Local Supplier Development

Nissan’s investment strategy includes substantial commitment to developing local supplier networks that can meet the company’s exacting quality standards. This approach creates opportunities for Australian businesses to become integral parts of the global automotive supply chain.

The company has allocated significant resources to supplier training programs and quality certification processes. These initiatives aim to build long-term partnerships that benefit both Nissan and local businesses while strengthening the regional automotive ecosystem.

Technological Innovation and Future Readiness

Electric Vehicle Production Capabilities

The new Australian facilities are being designed with electric vehicle production as a primary consideration from the outset. This forward-thinking approach positions Nissan to capitalize on the rapidly growing demand for sustainable transportation solutions.

Battery technology integration and charging infrastructure development form key components of the overall investment strategy. The company recognizes that future automotive success depends heavily on embracing electrification trends.

Research and Development Centers

Beyond manufacturing, Nissan is establishing dedicated research facilities focused on developing solutions specifically for regional market conditions. These centers will concentrate on addressing unique challenges presented by Australian climate conditions and driving patterns.

Collaborative partnerships with local universities and research institutions are being forged to leverage regional expertise. This approach aims to accelerate innovation while building lasting relationships with the Australian academic and scientific communities.

Addressing Critics and Skeptics

Financial Sustainability Concerns

Some industry analysts have questioned whether the investment scale is financially sustainable given current market conditions. Nissan leadership has responded by emphasizing the long-term nature of their strategic planning and commitment to the Australian market.

The company argues that short-term financial metrics don’t adequately capture the strategic value of establishing a strong manufacturing presence. They point to successful examples of similar long-term investments that initially appeared costly but ultimately proved highly profitable.

Risk Management Strategies

Comprehensive risk assessment processes have been implemented to identify and mitigate potential challenges that could impact the investment’s success. These include currency fluctuation risks, regulatory changes, and market demand variations.

The company has developed contingency plans for various scenarios that could affect operations. This proactive approach demonstrates Nissan’s commitment to protecting its investment while maintaining operational flexibility.

Global Context and Industry Trends

Automotive Industry Transformation

The global automotive sector is undergoing unprecedented transformation driven by technological advancement, environmental regulations, and changing consumer preferences. Nissan’s Australian investment positions the company to navigate these changes effectively.

Traditional manufacturing approaches are being replaced by more flexible, technology-driven systems that can adapt quickly to market changes. The Australian facilities incorporate these modern principles from their inception.

Regional Competition Dynamics

Other major automotive manufacturers are also making significant investments in the Asia-Pacific region, creating intense competitive pressure. Nissan’s Australian strategy represents a direct response to these competitive challenges.

The company believes that first-mover advantages in establishing comprehensive Australian operations will provide lasting competitive benefits. This positioning should help secure market share as regional demand continues expanding.

Environmental and Sustainability Considerations

Carbon Footprint Reduction

The new manufacturing facilities incorporate advanced environmental technologies designed to minimize carbon emissions and environmental impact. Nissan has committed to achieving carbon neutrality across its Australian operations within specified timeframes.

Renewable energy integration forms a cornerstone of the environmental strategy, with solar and wind power systems being installed at major facilities. This approach aligns with Australia’s commitment to reducing greenhouse gas emissions.

Waste Management and Recycling

Comprehensive waste reduction programs are being implemented across all manufacturing operations, with ambitious targets for recycling and reuse. The company aims to achieve near-zero waste-to-landfill status through innovative processing technologies.

Material recovery systems will capture and process manufacturing byproducts for reuse in production processes. This circular economy approach reduces both environmental impact and operational costs.

Future Outlook and Expansion Plans

Market Growth Projections

Market analysis data suggests strong potential for continued growth in Australian and regional automotive demand over the coming decades. Nissan’s investment strategy is designed to capitalize on these favorable trends.

The company expects its Australian operations to serve as a regional hub for distribution to neighboring markets. This expanded role could significantly increase the investment’s overall return potential.

Technology Evolution Adaptation

Continuous technological advancement will be necessary to maintain competitive advantages in the rapidly evolving automotive sector. Nissan has committed to ongoing investment in upgrading and modernizing its Australian facilities.

Innovation partnerships with technology companies and research institutions will ensure access to cutting-edge developments. This collaborative approach should help Nissan stay ahead of industry trends and customer expectations.

Frequently Asked Questions

Q: How much is Nissan investing in Australian manufacturing? The total investment is estimated to exceed several billion dollars over the next decade, including facilities, technology, and workforce development.

Q: When will the new manufacturing facilities be operational? Production is expected to begin in phases, with initial operations starting within the next two years and full capacity reached by 2027.

Q: How many jobs will be created? Thousands of direct jobs are expected, with additional indirect employment opportunities through supplier networks and service providers.

Q: Will the facilities produce electric vehicles? Yes, the facilities are specifically designed with electric vehicle production capabilities as a primary focus.

Q: What makes this investment strategic for Nissan? The investment provides regional market access, supply chain resilience, and positions Nissan for future growth in the Asia-Pacific region.

Q: How will this impact Australian consumers? Consumers should benefit from improved vehicle availability, faster delivery times, and potentially more competitive pricing.

Q: What environmental measures are being implemented? The facilities will incorporate renewable energy, waste reduction programs, and carbon-neutral operations as key environmental priorities.

Q: Will this affect Nissan’s global operations? The Australian investment is designed to complement and strengthen Nissan’s global manufacturing network rather than replace existing operations.

Q: How does this compare to competitors’ investments? Nissan’s commitment represents one of the largest automotive manufacturing investments in Australia in recent years.

Q: What risks does Nissan face with this investment? Key risks include market demand fluctuations, currency variations, and regulatory changes, all of which are being actively managed through comprehensive planning.